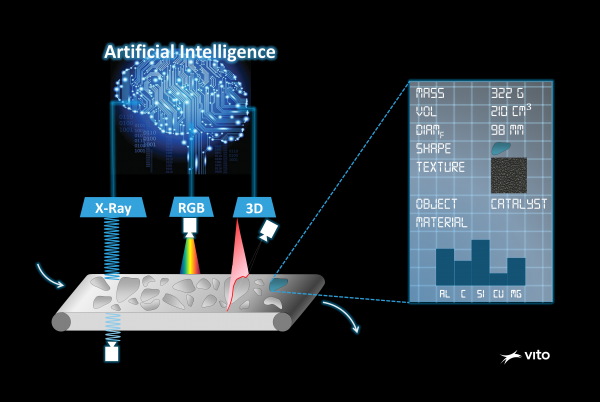

To counter this, VITO initiated the development of an in-line characterisation technology. This way, heterogenous and complex material streams can be assessed completely – eliminating the need for subsampling – and mass-balances can be produced ‘on-the-fly’. In fact, for each material particle a ‘digital twin’ is created which can be further assessed in a virtual way. In this technology, the heterogenous waste particles are dispersed on a conveyor belt as a mono-layer and scanned using X-rays, a 3D laser scanner and a colour camera. Using artificial intelligence, the device recognises the individual particles and assigns several important physical parameters: size, mass, shape, material, texture, etc.

Currently the technology is demonstrated successfully for a handful of streams on the level of relatively small samples, e.g. a few buckets (‘scan-the-bucket’). In the current CHARAMBA proposal, VITO wishes to further mature the technology, i.e. scale it up to an industrial relevant level or, in other words, to ‘scan-the-truck’. The project will focus on two required innovations: (1) a framework to efficiently tailor hardware, software and models to new streams and customer challenges and (2) a performance scale-up of the technology, to deal with industrially relevant throughput and provide stream statistics in real-time.

To take on this challenge, VITO partnered with Ghent University and two industrial partners, Suez and Umicore allowing to showcase the industrial relevance of the new characterisation technology.

After project completion, VITO wishes to introduce the innovative technology as a service to the market and subsequently launch a spin-off company selling tailor-made inline characterisation devices to several players in the metal recycling market.

Key facts

CHARAMBA stands for: artificial intelligence for material CHARActerisation & real-time Mass BAlances

Funded by EIT RawMaterials as Upscaling project under project no. 19128

Project duration: 01/01/2020 to 31/12/2021

Funding budget: 1 523 033 €

TRL at project start: 5 (Technology validated in relevant environment)

TRL at project end: 7 (System prototype demonstration in operational environment)